Table Of Content

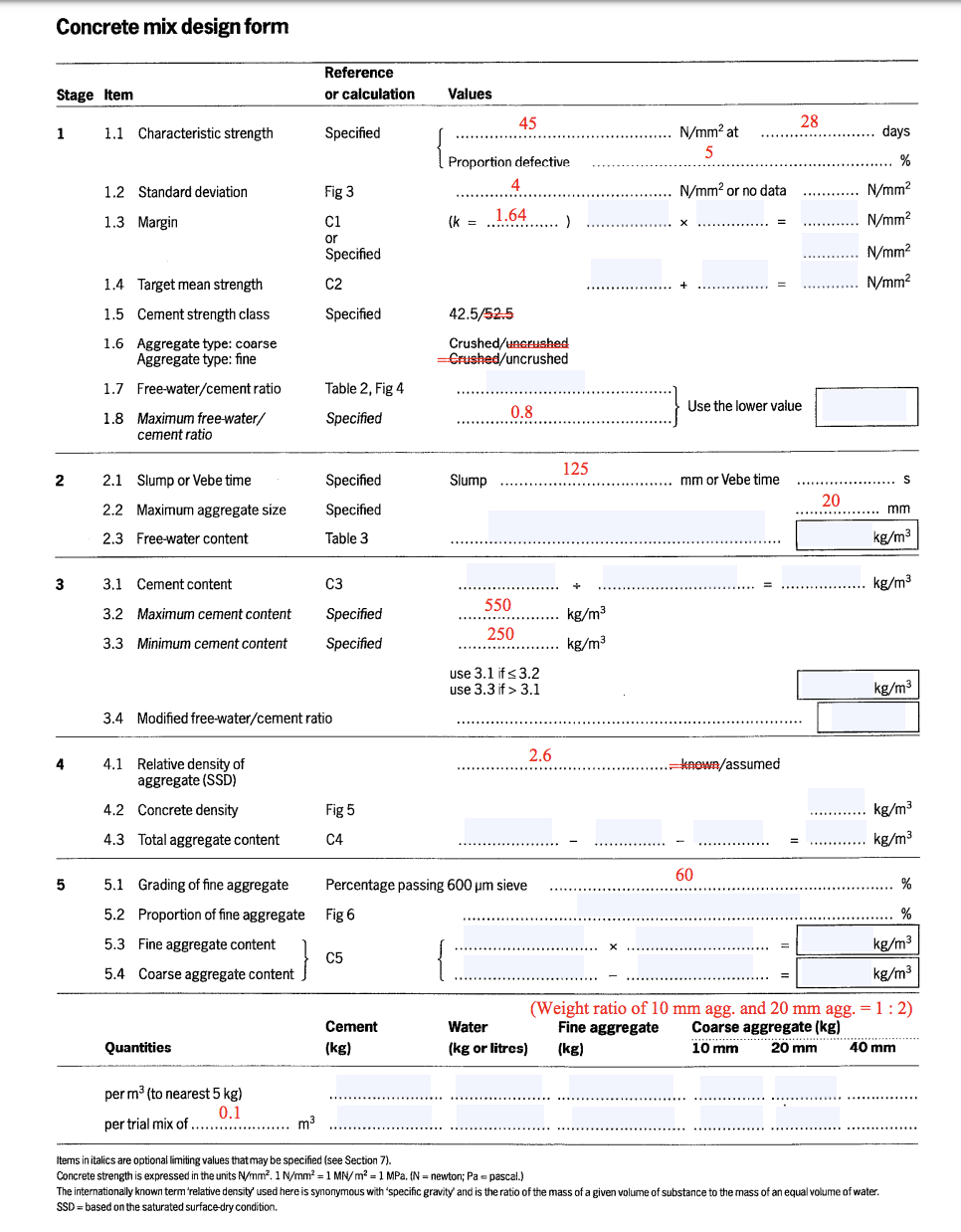

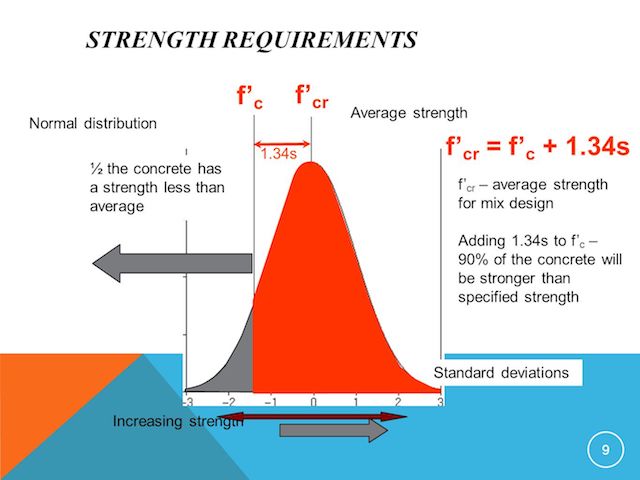

The mix should also be designed to be workable and to achieve the desired strength and durability. Quality control is improved, work efficiency increases, and cost savings can be achieved. Additionally, creating mixed designs can be tailored to meet specific needs, such as strength requirements or environmental considerations.

Chromatic Butter Yellow Tips

Once the proportions have been determined, the concrete must be tested to ensure it meets the desired properties. The testing process is necessary to ensure that the concrete will perform as desired and meet the specified standards for strength, durability, and other characteristics. The right ratio of concrete mix materials can solve problems and the wrong mix can create them. The first resource that must be obtained for any concrete project is protective equipment and materials. Proper protective gear, such as safety goggles, gloves, and hard hats, should be worn at all times to ensure the safety of all personnel working on the project. In addition, any materials and tools used to create the mix design must be of the highest quality and meet all applicable safety standards.

What Is Concrete Mix Design?

Water is used to activate the cement, while aggregate provides the structural strength and workability of the mix. Admixtures are additional ingredients that can be used to improve the performance of the concrete mix by altering its properties. In concrete mix design, SCMs are used to replace a portion of the cement to make the concrete more cost-effective and environmentally-friendly to produce. Depending on the SCMs used, the concrete may also gain other properties like slower set time or higher strength. Concrete mix designs that include set accelerating admixtures will have a shorter setting time and increased early strength development.

TB-1301 – Hydration stabilizer applications and performance review

Flatwork, underground pipes, bridges, walls - they all require concrete with different properties. Nominal concrete refers to the mix proportions of the concrete, typically expressed as a ratio of the volume of cement to the volume of aggregates (sand, gravel, or crushed stone) to be used in the mixture. Nominal concrete mix ratios are often used as a guide to achieve the desired strength and workability of the concrete. The nominal mix is the process in which all the ingredients are prescribed as per specifications and their proportions are specified in the ratio of cement to aggregates for a certain strength achievement. The proportions of ingredients in the nominal mix are the same for all the projects.

Data Required Mix Design

Individuals working on the project should thoroughly understand the process, components, and strategies of creating mixed designs. This includes clearly understanding the types of materials and tools required and the process of creating the mix design. Gaining a thorough understanding of concrete mix design is crucial for quality construction. Contractors should learn the basics of concrete mix design, including the components and the process of creating concrete mixes.

Once you have a good amount of pins on a board (15-20) look for common themes. Write those themes down in a note in your photo along with other details you will need while decorating your space including dimensions and a list of things you may need. The rustic elements in her space include her hood vent, the deer in her living room and dining, and the leather sofa, really all the warm accents.

Connect With ACI

You’ll see tons of farmhouse elements like her lights, tile, and most of her accessories. Generally, mixes of the stiffest consistency that can still be placed adequately should be used (ACI, 2000[1]). Typically slump is specified, but Table 1 shows general slump ranges for specific applications. Slump specifications are different for fixed form paving and slip form paving. From the above curve, you can choose the w/c that achieve the strength requirements. This value depends on whether the concrete is air-entrained or not.

Benchmarking Cracking Resistance of Alabama Mixtures - Auburn Engineering

Benchmarking Cracking Resistance of Alabama Mixtures.

Posted: Thu, 18 May 2023 21:55:30 GMT [source]

Keep things earthy and cool-toned with these blue, white, and brown swirls that mimic the whimsical look of watercolor paintings. Although these are technically classic white French tips, the heart-shaped cutouts and chromatic details make this set anything but basic. Micro French nails are Kendall Jenner’s current signature mani, making these cherry mocha-colored mini tips supermodel-approved. One way to get the right mix for your application is to have a great relationship with your ready mix supplier.

Framework for Balanced Mix Design - Auburn Engineering

Framework for Balanced Mix Design.

Posted: Wed, 16 Jun 2021 00:26:29 GMT [source]

Concrete producers and contractors get more value out of conventionally proportioned control flow concrete by reducing placing time and labor costs. If you have a design that you want to incorporate in your home but are struggling to make it happen phone a friend that has that design style. It’s always nice to get a second pair of eyes on a project to help you get inspired. It also will help you with any commitment issues you might be having with your design. So often I find that people just don’t design a space because they simply are afraid they aren’t going to like living with that style for long. If you start with a neutral palette and mix styles with accessories it’s not as scary to jump in.

To create a concrete mix design, the concrete ingredients must be identified. The most common ingredients used in concrete mixes include Portland cement, water, aggregate, and admixtures. Each of these ingredients plays a different role in the final product. Concrete mix design is the science of choosing the types of ingredients, and the proportions to use them in, to create concrete that meets the technical specifications for a given construction project.

We’ve decided we’re going to use Romabio paint products and we let our community vote on the color (because they were all amazing & I couldn’t decide). You can use Canva or a grid app and put photos of the pieces of furniture you like all together. It doesn’t need to be anything formal but having your bigger purchases all together to see how you feel about it will help wrap your head around your design.

You can then tell him what your application is, when you plan to place, and what the specification requires and he can develop the ideal mix. There's nothing wrong with this if you have a very knowledgeable producer and tell them precisely what you need. But understanding what's going on in the mix is still your responsibility. Appearance issues are obviously more important for decorative concrete than other applications.

One of the most important aspects of mastering concrete mix design is understanding the essential components that go into it. A successful mix design should account for the characteristics of the aggregate and cement, the desired strength and durability of the concrete, and the environmental conditions the project is in. Once these elements have been identified, the mixed design can be created from scratch or modified from an existing one.

Controlled concrete is typically used in large construction projects where the quality and consistency of the concrete are critical to the safety and performance of the structure. The nominal mix is site-level mixing small concrete mixer can be used to mix the ingredients. Whereas the design mix is designed from ready mix concrete plant that is RMC plant. The volume of coarse aggregate is required to be increased to reduce the fine aggregate content in the mix. If the water-cement ratio is more than 0.5, the volume of coarse aggregate is to be reduced to increase the fine aggregate content.